If you find this article useful and you would like to support the work we do as an All Ability Cycling charity please consider sending us a small domain via our PayPal Charity fund page.

If you follow our posts you will be aware of one of our local riders David Wilson who suffers from MND. along with his Wife Helen they make up a amazing team on there ‘Bike Train’.

Up until recently David has still maintained some arm movement and crucially a little grip, and with this grip he was able to still change gears through the use of the fantastic Archer Electronic gear shifter using their Archer Drop bar remote. with the buttons attached to his Recumbent grips. Unfortunately as David’s condition has deteriorated, more recently he is finding it ever more difficult to activate the buttons and change gear when required. As David’s legs are still allowing him to pedal and give the bike train it well needed extra push we wanted to investigate other options for giving David a way to continue to change his gears.

Options

The Archer Drop bar buttons are connected to the Archer remote using a very standard 3.5mm ‘audio jack’ so interfacing with them should be very straight forward. simply replicating the buttons with either a relay to make the contacts or even directly interfacing with a small microprocessor board like an Arduino should be possible. So as long as we can find a method for David to trigger two separate commands ‘UP’ and ‘DOWN’ we should be able to figure out a solution.

Another very nice feature of the Archer Kit is that it supports the detection of a ‘Long’ press that can then switch to a specific gear. so dropping from top to bottom gear on a 8 speed derailleur does not necessarily require 8 x ‘Down’ gear commands which would definitely help with approaching of a steep hill.

So what are our options that we think David could control?

Voice Activation

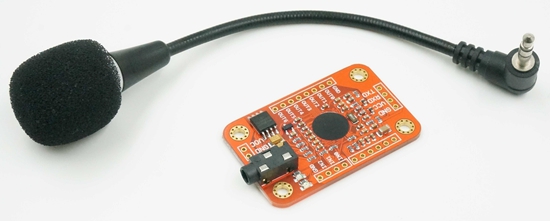

There are small electronic boards that can lean multiple voice commands such as the words ‘UP’ and ‘Down’ and ‘Bottom’. one device that would be easy to work with is the ‘Elechouse Voice Recognition Module V3.1‘

This has the ability to directly switch up to 7 outputs on or off and through the use of Relays this could easily be connected to simulate button presses.

I experimented with one of these units and it is promising however my main concern is how acurate it would be detecting the voice commands while riding the bike due to the added wind noise. In my testing it is very accurate in detecting the voice commands when trained and tested in the same exact location but even a change in the acoustics of the room seams to quickly cause it to not pick up on the commands reliably. I will continue to experiment with this module and maybe try out different more sensitive microphones to see if it can do the job reliably.

What I do like about it is that its very easy to work with and can be either interfaces with an Arduino Micro processor board for custom functions or even be run standalone with or without a relay board attached.

Air pressure Sensor to create a ‘Suck/blow’ switch

Another commonly used method for commuter control by people without the use of there body movement is a air pressure sensor with a mouth pip attached. this is commonly referred to as a ‘suck/blow’ switch as the name defines the function. the user can either gently suck on the pipe to trigger the switch one way, or blow to trigger it the other way. doing nothing registers a off state. This would give us the ability to for example blow for up gear, suck for down gear.

looking around google there does appear to be commercially available products designed for medical equipment, but its unclear what the cost would be and also its not clear if these are simply a single switch for example. a patent could blow into the pipe to raise the Nurse call alarm. Another Example using a drink bladder!

I decided to go down the DIY approach and see if we can build something our self.

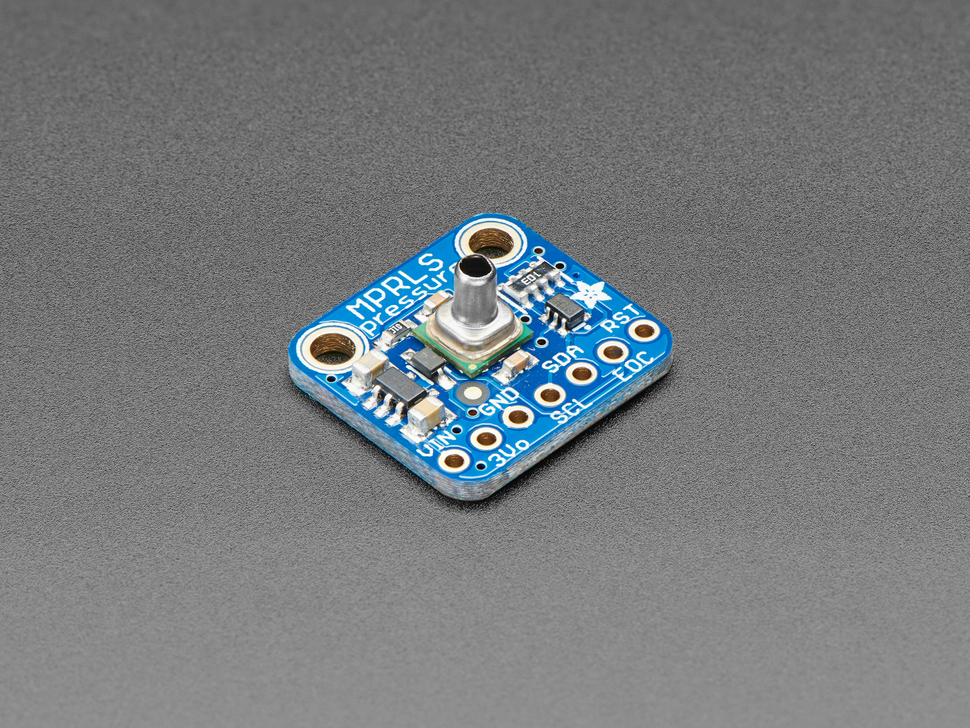

so after a bit more googling I found the Adafruit MPRLS Ported Pressure Sensor board

This small circuit board has a tiny air pressure sensor in the middle that you can attach a 2.5mm pipe to. It can detect 0-25 PSI so is ideally suited to detecting Air pressure which typically sits around 14.7 PSI at sea level, conveniently sitting right in the middle of the sensors range. This should make it very easy to detect a small change in pressures either positive or negative from sucking or blowing on the pipe.

So I got to work making a small prototype..

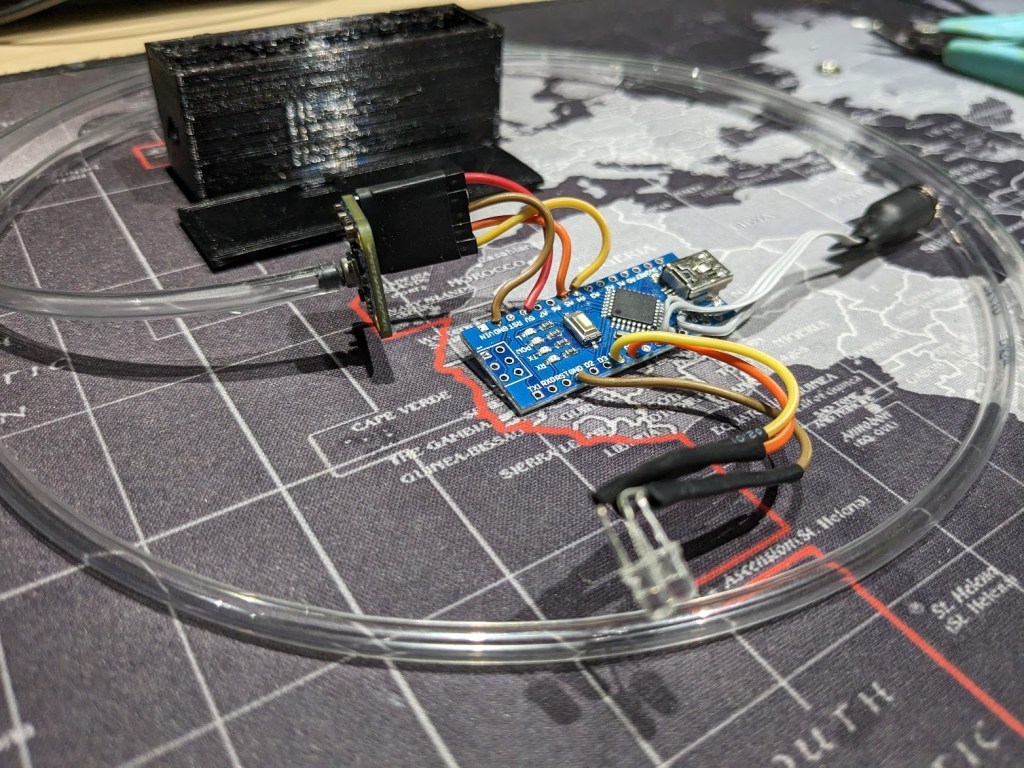

So here is the first prototype with the sensor connect to a pipe, electrically connected to a small Arduino Nano Microprocessor with two Led’s showing detection direction and an output connector to hopefully interface with the Archer Remote.

With a little Arduino coding Its easy to detect suck and blow commands…

In fact its even possible to detect a long ‘blow’ and use this to potentially trigger a long press and drop to the lowest gear!. this has potential.

The next step was to 3D print a suitable housing to do some testing with..

First try connecting to the archer remote.

Update – 23rd March

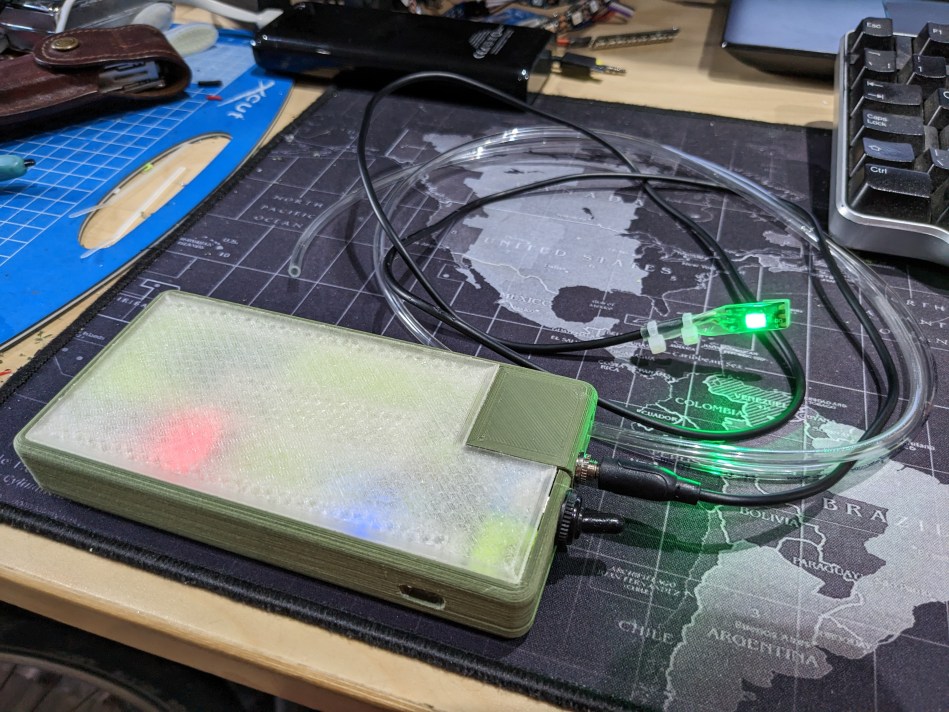

The next step was to bring all the components together into a single Housing. I wanted to do this before trying it out in the wild to eliminate any possible issue from things becoming unplugged. So this week I designed a new housing that fits around an old 2.4Ah flat Lipo battery I had in my spares box. I added a tiny USB C lipo charging circuit and a DC boost circuit to provide a solid 5v for the Arduino, and i removed the Circuit board from the Archer remote, and fitted it all with a 3D printed shelf within a larger Box.

The 3.5mm jack is used to connect a RGB LED which can be attached to the riders helmet so giving them visual feedback when a gear has changed. I Also added code to detect when the battery was getting low so flashing the LED to give them some warning before it simply runs out. However with a battery that’s almost 10 times bigger in capacity than the original Archer battery I think this thing could cope with many hours use between charges!

Here is david testing the controller for the first time in the Hub.

A new rear wheel hub just coming on to the market might prove to have an application I hadn’t thought of. I have a test & evaluate hub coming & can report on it’s effectiveness by this Summer. This hub is an automatic shifting 3 speed internal hub. Cable or Shifter operation is not required for the hub to shift up or down through the gears. It is fully automatic & is controlled using centrifugal force. Although it may seem limited with only 3 gears, many of us grew up with bikes with only 3 gears so this may be fine with a small power assist. A 5 speed hub is under development for fat bikes & trikes.

LikeLike

Pingback: Mouth Controlled gears Version 2 – Empowered People